Introduction

The purpose of this article is to provide commentary and outline strategies to reduce the transmission of airborne infectious diseases with respect to commercial air conditioning systems. The article is intended to provide general guidance principles but cannot cover every type of installation of air conditioning system installed throughout the range of buildings encountered.

The guidance principles discussed are not engineered solutions and cannot be applied without due consideration of all potential consequences. We strongly recommend seeking professional advice on a building by building basis prior to implementing any of these principles.

For specific advice relating to a particular building, please contact us to arrange a site inspection.

General Information

A common method for transmission of airborne infectious diseases is via large water droplets and small water particles, which are released by an infected person when coughing, sneezing, shouting and speaking.

Shouting and speaking can produce water droplets which can travel up to 1 metre from a person. Water droplets are generally heavy, so do not readily enter most ventilation systems.

Small particles (aerosolised water droplets), typically produced when a person coughs or sneezes. These particles can stay airborne for extended periods of time and can travel relatively long distances. These aerosols are buoyant and can be drawn into air conditioning units and ventilation systems.

Standard grade filters fitted to recirculating fan coil units or the indoor sections of typical air conditioning units can capture a portion of these aerosols. If the concentration of aerosols is high, the likelihood increases that more will pass through the filters and be re-distributed back into the occupied spaces. This transmission method has been demonstrated in small spaces with high occupant densities and high airflow rates, such as in aircraft, but there is limited evidence of this occurring within typical building air conditioning systems.

An important role of a standard air conditioning system is to introduce adequate outdoor air into the occupied spaces of a building, ensuring adequate oxygen is supplied to the building occupants and the dilution / removal of impurities released into the air by furnishings, as well as the removal of odours from respiratory functions.

Inadequate quantities of outdoor air or a lack of overall air movement means that the air within the occupied space is not removed and replaced at a sufficient rate. This allows dust particles or aerosols carrying pathogens to remain present within the space for longer, thus increasing the likelihood of contamination by direct contact or being inhaled by the occupants. This effectively increases the likely rate of transmission of airborne infectious diseases.

The strategies discussed in this document cover those which apply to common HVAC (Heating Ventilation and Air Conditioning) systems.

HVAC Based Strategies

Configure Air Conditioning Systems to ‘Single pass’ Full Outdoor Air

This is a dilution strategy which applies to central plant air handling systems that supply large volumes of conditioned air to multiple spaces / floors within a building.

The system is configured so full outdoor air is drawn into the air conditioning system from outside, supplied to the occupied spaces and then actively removed or passively leaked out of the building directly to outside. In this arrangement no air removed from the occupied space is recirculated via the air conditioning system back into the occupied space.

The benefit of utilising full outdoor air is it reduces the opportunity to spread airborne infectious diseases throughout the building, as no recirculation occurs. The pathogen load is limited to only that being generated within each space at that time.

Side effects from manually configuring an air conditioning or ventilation system to utilise full outdoor air at all times are:

- It may lead to uncomfortable internal temperature and humidity levels due to the considerable increase in heating and cooling loads imposed by the high quantities of outdoor air. The original systems were not designed to cope with these additional loads.

- The internal temperature and humidity will tend to be above or below that prevailing outside the building. For example, on a very hot and/or humid day the reduction of occupant comfort may lead to complaints and a loss of staff productivity.

- Note, some central plant air conditioning systems such as those which utilise direct expansion refrigeration coils for heating or cooling the incoming air, may not be suitable for configuring to full outdoor air operation.

Specific assessment of your plant is required to determine its suitability to provide full outdoor air ventilation.

Increase Outdoor Air Flowrates to Occupied Spaces

This is an alternative dilution strategy which applies to either central plant air conditioning systems or decentralised systems such as fan coils units, with outdoor air being supplied by dedicated outdoor air systems.

If an existing air conditioning system cannot be configured to operate on full outdoor air mode, an alternative approach is to increase the flowrate of outdoor air supplied by the installed system. This is most easily accomplished by increasing the speed of the outdoor air fans, which will in turn increases the volume of outdoor air provided to each space within the building.

By increasing the outdoor air flowrate, the amount of dilution of contaminants in the occupied space is increased, so reduces the risk of transmission of airborne infectious diseases. This effect has been demonstrated in studies undertaken by the American Society of Heating, Refrigeration and Airconditioning Engineers (ASHRAE) regarding the transmission of influenza.

Undertake a Night Purge Cycle

This approach can apply to all ventilation systems.

A night purge cycle is where the outdoor air (and any applicable exhaust systems) are set to run continuously, even while the building is unoccupied. This purges the building with outdoor air, so replenishes all the air within the building while no contaminants are being generated within. The occupants then return to a space where very little residual contaminants remain.

Most ventilation systems can be configured to undertake a night purge system by simply changing the time-switch settings or plant schedules within a Building Management System (BMS) to make the ventilation system fans run continuously.

Provided heating and cooling functions are either disabled or setpoints relaxed during times when the building is unoccupied, this approach may even decrease energy usage of the plant. However, the maintenance frequency will need to be increased as filters will require more frequent cleaning and some plant items will require to be serviced at shorter intervals.

Clean All Air Conditioning Unit and Ventilation System Filters

While standard grade air filters are ineffective against viruses, cleaning or replacing all air filters in the HVAC system will ensure the maximum amount of air can flow through the system, so occupied spaces receive the maximum number of air changes per hour.

To an extent, this helps to increase the dilution rate of contaminants and minimise stagnation of air within pockets of the building. Studies have demonstrated that stagnation of air in buildings increases the transmission of airborne infectious diseases, due to a reduction in the rate of removal of particles transporting bacteria or viruses. Infected particles are more readily inhaled or transmitted between the building occupants.

Filters suspected to be contaminated serving the local fan coil / indoor units, or in any recirculating ventilation systems should be replaced by new filters, with the removed filters carefully disposed of by incineration.

This also applies to washable media filters typically found in fan coil units and split system indoor units, as washing this media could expose maintenance staff to live bacteria and viruses.

Furthermore, we recommend all maintenance staff use disposable nitrile gloves and suitable face / respiratory protection when changing potentially infected filters. A high level of personal hygiene is also required similar to that adopted when working with HEPA filters.

Retrofitting HEPA Filtration in Ventilation Systems

High Efficiency Particulate Arrestance (HEPA) filters are designed to capture very small particles and are effective at capturing water droplets and aerosols. They are typically found in specialist applications such as cleanrooms, operating theatres, isolation rooms and the like.

To achieve their high levels of performance, HEPA filters utilise a fine weave of fibres causing only small gaps to exist within the filter for air to pass through them. As a result, the filters are typically considerably larger than standard efficiency filters found in commercial office applications and they require the fan and duct system to develop much higher pressures in order to drive the required volumes of air through the filters.

Consequently, unless a ventilation system has been specifically designed to cope with the high system pressures, retrofitting of HEPA filters to a standard ventilation system will overwhelm the fan and cause the system to underperform.

A typical commercial ventilation system does not include HEPA filtration and we believe it is not practical to retrofit HEPA filters to typical commercial ventilation systems as an immediate countermeasure to the transmission of airborne infectious diseases.

Portable Air Cleaners with HEPA filters

In-room air cleaning units contain a fan to recirculate the air within a room through prefilters and a HEPA filter to ‘clean’ the room air. This is an effective alternative to providing HEPA filtration within the ventilation systems.

These systems will not completely remove all particles and water droplets from the air as they can only serve a local area, but the number of residual particles available for recirculation via the in situ ventilation and air conditioning systems will be reduced, lessening the chance of transmission of infected particles & water droplets.

Availability of suitable units at short notice may be a limiting factor to this strategy.

Noise generation from portable air cleaners should also be considered.

Retrofitting Ultra-Violet Germicidal Irradiation in Ventilation Systems

Ultra-violet Germicidal Irradiation (UVGI) is a technique to disinfect air streams, whereby UV lamps are installed within a section of ductwork or within an Air Handling Unit. The systems generate UV-C radiation that when applied at the correct dosage, will effectively kill all bacteria and viruses which are either contained within or attached to dust particles or contained within water droplets within the air stream. This method is proven to be an effective means of disinfecting an air stream.

A requirement of this system is for the air stream to be exposed to the UV-C radiation for a specific minimum amount of time. This typically results in the UVGI system being quite large in both cross sectional area and in length. As for HEPA filters above, if a ventilation system has not been specifically designed to accommodate a UVGI system, it can prove to be very impractical to retrofit into an existing system.

For many existing commercial air conditioning and ventilation systems, the practicalities involved will limit the ability to effectively retrofit this technology as an immediate countermeasure to the transmission of airborne infectious diseases.

On the assumption that a source of clean outdoor air is available, if recirculating systems are avoided, the UV-C systems are not required to the same extent.

Hospital Isolation Rooms

The following general information on the principles of Isolation Rooms is included for general knowledge given the current public interest in managing airborne infectious diseases.

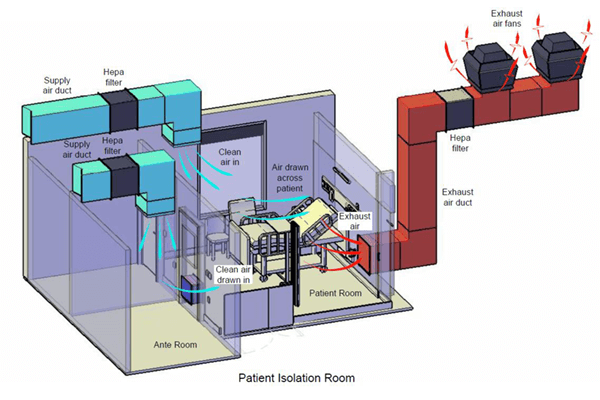

Isolation rooms, or more correctly ‘negative pressure rooms’ when used to manage airborne infectious diseases, are specially designed rooms to contain the spread of airborne bacteria and viruses from infected patients.

The concept is relatively simple, refer schematic representation above, in that an amount of conditioned air (heated or cooled and filtered) is supplied into a well-sealed room, with a higher quantity of air being extracted out of the room at all times.

Consequently, a negative pressure is created within the room, so that air continuously leaks into the rooms and no contaminated air escapes from the room. When the door to the room is opened, air will rush through the door into the room.

The potentially contaminated air being drawn out of the room is cleaned by passing it through High Efficiency Particulate Arrestance (or HEPA) filters, with the cleaned air typically being exhausted vertically at and high speed and at high level to maximise dilution of the discharge.

Isolation rooms are specially designed and built to a high standard with a high degree of airtightness, to ensure the negative pressure can be maintained at all times. Ease of cleaning all surfaces within the room is also a key consideration.

The operation and performance of Isolation rooms is continuously monitored by control systems and includes visual indication to the medical staff confirming that the negative pressures are being maintained at all times.

Access to isolation rooms is typically limited to medical staff who wear special protective clothing, with access closely managed by hospital staff.

Non-HVAC Based Strategies

Non-HVAC based strategies for the control of airborne infectious diseases in the workplace typically include encouraging high levels of personal hygiene, consideration towards the wellbeing of others, high standards of workplace cleaning and the isolation of sick staff.

With respect to the current 2019-2020 Coronavirus outbreak, advice on the above is available from the World Health Organisation and the Centers for Disease Control websites.

Please follow the links below for more information.

https://www.who.int/emergencies/diseases/novel-coronavirus-2019/advice-for-public

https://www.cdc.gov/coronavirus/2019-ncov/specific-groups/guidance-business-response.html

https://www.health.govt.nz/our-work/diseases-and-conditions/covid-19-novel-coronavirus

Please note: the advice provided by these organisations is being updated frequently as more study is undertaken on COVID-19 (Coronavirus) as the situation develops, so check for the latest advice frequently.